- Home-

- Products-

- All Products

- --------------

- Mobile Steps

- Roll Pallets & Roll Cages

- Stillages & Pallet Cages

- Warehouse Platform Trolleys

- Pallet Converters & Pallet Retention

- Folding Wire Pallet Cages

- Container Ramps

- Plastic Pallet Boxes

- Aluminium & Glassfibre Ladders

- Tipping Skips

- Shopping Trolleys

- Plastic Trucks Skips & Bins

- Hanging Garment Rails

- Chute Front Stillages

- Garden Centre Trolleys

- Load Restraint Range

- Post Pallets

- Pallets

- Plastic Tote Boxes

- Sack Trucks

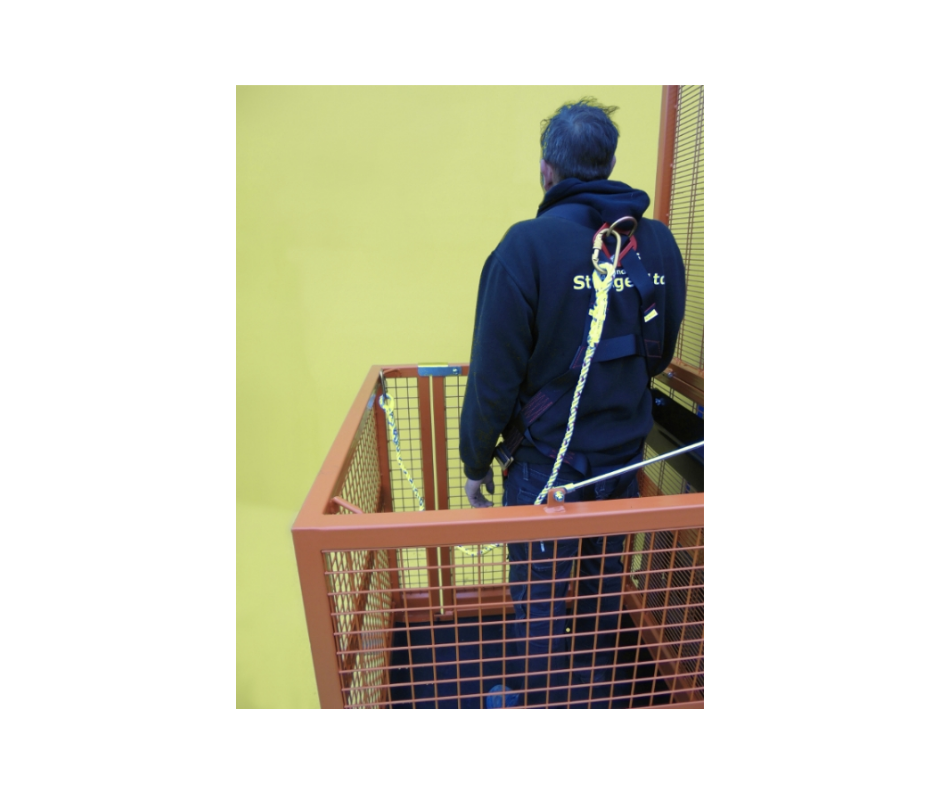

- Forklift Safety Access Cages

- Gas Bottle Storage & Cylinder Handling

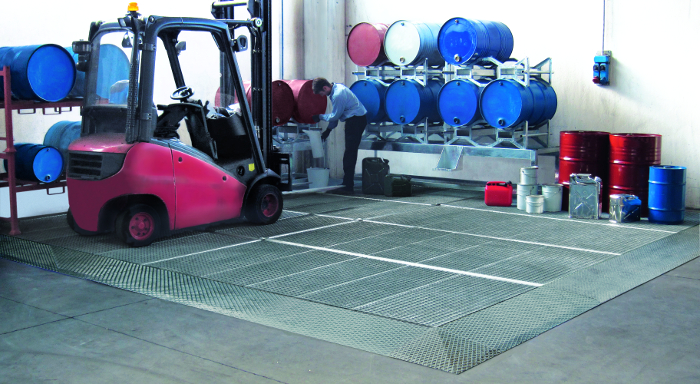

- Spill Containment, Sump Pallets & Flooring, Storage of Hazardous Products

- Bulk Bag Holders and Handling

- Castors & Wheels

- Second Hand-

- CustomManufacture

- Rental-

- AboutUs

- Blog-

- Details

Most warehouses and distribution companies use pallets on a daily basis, so it's crucial to choose the most practical type for your business needs. If you're still utilising traditional pallets, it could be worth your while switching to roll pallets instead.

- Details

Tipping skips are used for quickly and efficiently handling waste materials in a variety of commercial and industrial settings. Usually used in conjunction with a forklift, they can minimise the time it takes to process your commercial waste products through a waste disposal or recycling system. There's a great range of used tipping skips available, offering you some clear benefits over new - especially during lockdown. Here are three reasons you should think about investing in used tipping skips.

- Details

Forklift trucks are the work horses of warehouses across the retail, distribution and manufacturing sectors, and can be made even more versatile by investing in the right accessories. Used well, interchangeable forklift accessories can boost productivity and give you a safer working environment. Here are three of the best forklift accessories we recommend owning to get the best performance value and versatility from your forklift.

- Details

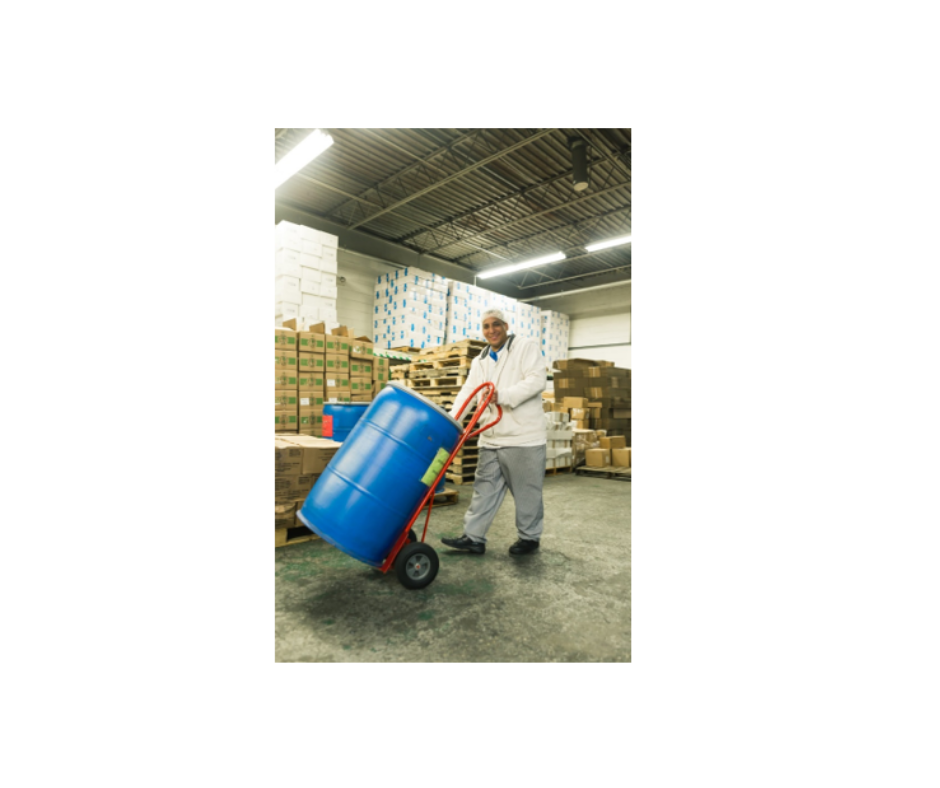

Sack trucks can help improve warehouse transport, streamline key operations and help your business become more efficient. In this article we look at the specific ways in which a sack truck can benefit warehouse businesses.

- Details

If your business uses roll cages, it pays to invest in quality products. Poorly manufactured roll cages can seem like they save you money on the surface, but can actually lead to several ongoing issues - and they could even cost you more in the long run than a superior product. Here are four reasons you should invest in high-quality roll cages designed for your purposes:

- Details

Spill containment pallets are essential storage solutions for businesses dealing with liquid hazardous materials (hazmat), especially oils, fuel, waste products, and chemicals. Put simply, a spill pallet (also known as a sump pallet) is a treated steel pallet or stillage with an in-built spill tray. Liquid storage drums can sit on it, on top of a grate. Below the grate, a sump catches any spillages. It's a simple piece, but one that can prove indispensable in avoiding spillages and reducing slip hazards in the warehouse. Here's why.

- Details

The ability to work at height is important in warehouses where space is at a premium but, despite strict health and safety legislation, falls from height are the main cause of deaths or serious injury in the workplace. In 2018-19, over 44,000 workers were injured, and an average of three people died every month because of falls. Perhaps understandably, warehouse operatives under time pressure may be tempted to take shortcuts when accessing heights, especially if they fail to appreciate the risks involved. However, most of the severe working at height injuries are sustained after falls of less than 2 metres.

- Details

2021 may have been a tough year for many industries, but e-commerce was definitely not one of them. If anything, last year was incredibly productive for online retail companies, which experienced an unprecedented boom in demand. This was especially evident during Christmas 2021, when nearly half of all non-food-related purchases were made online.

- Details

With the right trolleys and material handling equipment, transporting goods around the warehouse becomes more convenient and practical, as operators can ferry more goods to and from the warehouse dispatch points. Let’s explore the different trolleys you need for an efficient warehouse.

- Details

The plastic box pallet is an alternative to traditional storage devices that optimises how products, items, and records can be kept safe and secure while saving valuable space when they’re not in use. They come in closed-wall and perforated varieties. The boxes are typically purchased in mass quantities (150 or more) by industrial clients, although they’re also commonly seen in retail shops and domestic spaces.

- Details

A forward-thinking warehousing or retail business always jumps at the opportunity to get more value for less time, and that's precisely why you can't go wrong with high quality warehouse trolleys. These essential pieces of warehouse equipment have stood the test of time, and here are five of their greatest time-tested benefits:

- Details

Platform trolleys are essential in many businesses to provide an effortless way to move stock or goods - either heavy loads that could cause injury to staff if moved by hand, or small, light items that are difficult to move in bulk.

From retail outlets and garden centres to warehouses and storage facilities, employees and customers benefit from different types of trolleys and, at Steps and Stillages, we are delighted to be able to supply a variety of trolleys for industrial and commercial businesses, making us the one stop shop for this type of equipment.

- Details

There are several factors to consider when purchasing a pallet cage. Here is a checklist of eight questions to ask to narrow down your choice and ensure you buy the right product:

- Details

If it's time to replace your tipping skips, or if you're a first-time buyer, there are a few things to take into account. Not all tipping skips are created equally, and some are better than others for specific purposes. Get the right equipment for more efficient, productive work.

- Details

Steps and Stillages manufacture an enormous variety of steps, platforms, and platform ladders for use in businesses, warehouses, and for general mobility. If it's high up and you need to get to it, we have a solution to your problem. While our standard, heavy-duty steps are our most popular item, all our products are durable, reliable, well-made, and sold at a fair price. All of our equipment is made in the United Kingdom.

- Details

Forklift safety cages are a crucial part of any warehouse or distribution centre. Without them, there would be no way to protect workers from potentially deadly machinery. There’s a lot more to forklift safety cages than meets the eye, though, and there are some essential things you should know before making a purchase decision. In this guide, we’ll cover all about what safety cages are used for, best practices for safe use, and how to choose a good product.

- Details

Post pallets are widely used storage and transportation tools employed in warehouse settings. They provide several benefits over simple pallets or stillages in a number of industrial applications. From their stackable design to their affordable cost, here we’ll look at how a post pallet may suit your needs.

- Details

Ladders are an important piece of equipment in any warehouse. A good ladder will ensure that staff are able to perform their jobs safely and that they feel secure whilst working above ground level. A low quality warehouse ladder can lead to serious injury, which will affect both the worker and the business involved. To avoid accidents, you will need to choose your warehouse ladders carefully.

- Details

With their flexibility, versatility, and reliability, post pallets are the go-to option for many warehouse storage requirements. Their open sides are great for access, but should they be used for racking? Read on to find out!

- Details

Pallets are invaluable for the storage, stacking, and transportation of materials and are widely used in various industries due to their flexibility and ease of use. Built-in forklift pockets facilitate quick, accurate, and safe lifting of heavily loaded pallets so that they can be moved around a warehouse, construction site, or other location. When not in use, pallets can be stacked safely to minimise the storage space.

- Details

Roll cages, or roll pallets, are practical and versatile pieces of equipment. However, it's essential to select the most appropriate type for your company. Roll cages can be divided into several categories according to how they can be stored when not in use. Let's look at the three main types of roll cage that you can buy.

- Details

Working at height poses many challenges for business, least not the need to ensure that personnel are kept safe and that the chance of a fall is eliminated. In fact, due to the serious risk of injury or death if an accident was to occur, working at height is governed by the law, with the Work at Height Regulations (2005) placing a legal responsibility on employers to make sure that appropriate steps are taken to protect the safety of their workforce.

- Details

If your business processes potentially harmful chemicals, oils, or other industrial fluids, you’ll already be aware that spillages or leaks are a significant problem that can’t be ignored. Spilt chemicals or oil can be damaging to the environment, are costly to clean up, and pose a potential risk to the safety and wellbeing of your personnel. Fortunately, drum spill pallets provide a straightforward and cost-effective solution to the problem of chemical and oil spillage.

- Details

A warehouse is a bustling place. Pallets are stacked in towers, there's an endless stream of forklifts coming and going, and the constant sound of machinery creates a sense that anything can happen at any time. As you're stacking up pallets to save space and improve safety, it's easy to forget about what could go wrong when all these things come together. Let's look at 5 essential tips for stacking pallets in your warehouse from start to finish so that you and your team stay safe while saving valuable storage space!

- Details

If you need to keep gas cylinders on your company's premises, it's essential to store them properly. Failing to do so is a breach of Health and Safety Executive (HSE) regulations, and you could have to pay a hefty fine if caught. If a gas cylinder isn't stored appropriately, it may become damaged. That could result in a fire, an explosion, or the release of toxic gases into the air. So, how much will you need to spend on a gas bottle cage to ensure that your cylinders are secure, and what factors can affect the cost?

- Details

Steel stillages can store and transport goods around factory floors. There is no 'standard design' for this industrial equipment, which is often customised to accommodate specific products safely. It is easy to overlook the advantages of steel stillages, because they appear – at first glance – to be little more than metallic trolleys. Nonetheless, these storage cages greatly improve manufacturing efficiency, and are financially vital in commercial terms.

- Details

When you buy warehouse equipment, such as mobile safety steps, stillages, delivery roll cages, roll pallets, or trollies, fast delivery is an important and integral part of the service. However, it's crucial not to sacrifice the quality of your products in order to speed the purchasing process up. At Steps and Stillages, we aim to fulfil orders promptly, but also take time to ensure that our products are of the highest quality and meet rigorous safety standards. Let's see how this works in practice.

- Details

The timely removal of waste is an important part of day to day operations for many businesses, as its accumulation can pose health and safety hazards for employees and damage productivity in the workplace. Constantly ferrying waste from the production line to a central collection point is not an effective use of staff time and can also affect your business’s ability to dispose of waste in an environmentally friendly manner.

- Details

Hand trucks are extremely useful and versatile pieces of equipment that save your business time, effort, and money. But not all hand trucks are fit for the same applications. You want to look for the right solution for the task at hand, while also taking budget, safety, and ease of use into account.

- Details

Working with chemicals and hazardous materials in the warehouse can be dangerous, but you can mitigate the risk through safe transportation and storage of these materials. Hazardous material spills can put your employee’s health at risk, have a devastating impact on the environment, and be costly to clean up. Therefore, investing in spill management systems that reduce the risk to your employees and the environment in case of a warehouse spill is crucial.

- Details

Metal stillages provide a convenient and cost-effective solution that can be used for both goods movement and storage. Stillages hold your products securely and ensure that they are correctly contained while on the move. One of the most effective ways to transport products around a warehouse using metal stillages is by using a forklift truck. Let's explore how you can do this.

- Details

The battle against Covid in shops, warehouses and factories usually centres around physical distancing from colleagues, face masks, and plenty of hand gel, but the materials we choose for workplace implements can make a difference too. Our shopping trolleys are all zinc-coated, something which may be important when it comes to the fight against the Coronavirus.

- Details

Accidental liquid spillages are commonplace in industrial environments, so it is crucial that preventative actions are taken to reduce the risk of injury to personnel or damage to property caused by drips, leaks, and spills.

Spillages pose two main risks. Firstly, they can cause slips when employees move around the premises, which can lead to injury and absence from work. It’s important not to dismiss a slip as a ‘minor’ incident. Time off work from slip-related injuries dents your productivity, and slips can also lead to litigation if the worker claims damages from you.

- Details

They may appear inconspicuous, but those castors attached to your trolleys, carts and roll cages have more unique attributes than you might think. The choice of material - whether nylon, rubber, or steel - for your castors can depend on multiple factors; most importantly, what the platform is intended to be used for within your business. What kind of floor will these wheels be moving on? What kind of products will they be helping to transport? How heavy might the load be? These are the vital questions to ask. Here's how choosing the right castor material can have a big impact on your specific process and overall goals:

Load Bearing Capacity

Greater carrying weights will require larger diameter castors to cope with the extra pressure on the castors themselves and the floor surface. This is less about the actual strength of the castor than about it being able to spread the weight evenly as it moves over the surface. Larger castors also make it easier for operatives to control larger and heavier platforms, especially on smooth floors without much surface friction.

Floor Surface Material

Rubber castors are durable enough to accommodate large loads while also protecting sensitive resin flooring, which may be scratched and dinted by steel over time. Rubber itself is an incredibly sturdy material despite its softer texture and has no problems transporting most heavier loads. Carbon steel is the best option for castors when it comes to pure strength of the material, and these are well suited to tarmac and poured concrete floors, as well as outdoor surfaces. You may wish to use stainless steel castors for trolleys intended for hygienic environments – in laboratories, hospitals, food and pharmaceutical production facilities, commercial kitchens etc.

Noise Management

If noise is an issue for you - and it certainly could be for employees who have to be around it all day - rubber is a good choice as it dampens sound and can transport your goods relatively quietly compared to other materials. Rubber castors are frequently used on the heavy-duty trolleys and roll cages used in supermarkets.

Nylon castors should be considered as arguably a better option than steel for low-noise environments while capable of similar feats. Incredibly strong, nylon castors can help transport exceptionally heavy goods without being too noisy or damaging to your floors. Having been in use for almost a century now, nylon castors are still incredibly popular in industrial, commercial and retail settings, and are the castor of choice for many shopping trolleys.

Nylon Or Rubber?

Nylon and rubber castors are often used interchangeably on soft floor surfaces and noise-controlled environments. Where nylon castors may falter in comparison to rubber, however, is that they are less effective on uneven terrain (e.g. large retail carparks, outdoor garden centres) or in higher temperatures (e.g. horticultural propagation warehouses and commercial greenhouses). Whereas rubber can function effectively in these situations thanks to its exceptional durability, nylon is often restricted to flat and steady indoor surfaces, where it is hard to beat.

- Details

Starting on 1st April 2022, a new plastic tax will be implemented in the UK. What does this mean for companies that use significant amounts of plastic packaging, like warehouse and retail businesses? In this article we look at the impact of this new tax and at some practical ways of reducing additional expenses related to this development.

- Details

Warehouse platform trolleys vary widely in function, capacity, and quality, so before you invest your money buying a warehouse platform trolley, take a look at this brief guide to the main factors to consider.

- Details

One of the main variations in castor design is between rigid and swivel castors, both of which can be useful in different situations. Here’s what you need to consider before choosing one type of castor wheel over the other.

Range Of Movement Required

Rigid castors work exactly as their name suggests. They roll backwards and forwards in a fixed position, allowing movement in a straight line only. For this reason, they are also referred to as 'fixed' castors. A swivel castor, on the other hand, comes with a cylindrical mounting known as a 'raceway' that allows the wheel to turn up to 360° when necessary.

Operational Safety And Stability

Keep the working environment in mind, and the skill and experience of trolley operators, when specifying a castor type. If you foresee a lot of twists and turns in transporting goods around a warehouse, and they are only going to be used by trained employees, then swivel castors can offer that bonus movement and flexibility.

Something to consider though is that swivel castors sacrifice some strength and stability to achieve this, making them harder to control when overloaded due to the natural extra movement within the castors. It is not always advisable, therefore, to equip trolleys for customer use purely with swivel castors.

Some swivel castors can be locked in place to restrict movement and enable better control – and many trolleys use both rigid and swivel castors, e.g. rigid castors at the rear for stability and swivel castors at the front to enable steering.

Load Bearing Capability

Rigid castors are capable of carrying larger weights than swivel castors - what the rigid option lacks in manoeuvrability, it can make up for in sturdiness and strength. If you have a simple yet heavy job for it to do that doesn't require much change of direction – e.g. back and forth deliveries along a single warehouse trackway – a rigid castor could well be the best option.

- Details

When you’re working at height, you’ll want the reassurance that you’re fully protected against the risk of an accident. In the UK, thousands of workers are injured, some seriously, every year due to falls from height while, on average, several people die every month from injuries sustained in this type of tragic accident. As an employer or warehouse manager, you have ultimate responsibility for ensuring that your business complies with Work at Height Regulations, and for safeguarding your colleagues from one of the most common, but preventable, accidents in the workplace.

- Details

Pallets and stillages are both similar portable platforms that essentially provide the same function. In fact, stillage is simply a generic term for a heavy-duty steel-framed pallet variety - making the two part of the same family. Despite their similarity in use, however, there are still significant distinctions between the two. Here, we break down the pros and cons of stillages and pallets.

- Details

When you're ordering equipment for your warehouse, do you need to go down the bespoke path? Perhaps. It all depends on the particular needs of your company.

- Details

Waste is unavoidable in most businesses but, without a plan for its removal with the right equipment, clearing it can be a time-consuming chore that causes more problems than solutions. Fast-paced environments, such as warehouses, production lines and industrial plants, rely on highly orchestrated and organised work practices, so waste removal must support and boost productivity rather than hindering it.

- Details

For any warehouse, retail, or distribution business that handles large volumes of stock, proper transportation and storage management is crucial. Your storage strategy depends on the type and size of the products/stock and the available warehouse space. Collapsible pallet cages are a versatile storage solution that prevents product damage and maximises the available storage space when not in use. Read on to find out more.

- Details

A spill containment platform is any type of semi-permeable flooring, pallet, or loader base that can safely contain any spills from a storage unit (such as a plastic drum) placed for transport or stored on top of the platform.

- Details

Show the average person a picture of a stillage and they'll most likely know what they're looking at without being able to say what it's actually called, or the wide range of things it can be used for in warehouses, workshops, and shops. You can avoid falling into this trap yourself by brushing up on stillages and knowing the full extent of their potential.

Simple yet vital

On the surface, stillages look like sturdy pallets. Usually designed and made using carbon steel, they are used primarily for separating, storing, and carrying goods in factories and warehouses; a vital product that keeps the place functioning in the background. Many stillages are designed for easy transportation by forklift and, unlike many wooden pallets, stillages can be used repeatedly over ten years or more.

Making work easier

Stillages can greatly boost the productivity of any business that handles relatively small products in bulk, as well as larger and irregularly shaped items making life easier for warehouse operatives and forklift drivers alike.

Keeping the place tidy

Stillages can be stackable, ensuring they don't take up too much floor space themselves and helping optimise storage and space utilisation in the warehouse. Stillages make it easier for businesses to categorise items and find the products they need in a hurry, without investing in new shelving solutions or racking.

Customisation

At first sight stillages may appear hard to manoeuvre, but different options such as swivel castor wheels ensure they can move around better than you might initially think. Other options such as a drop-front or hatch door can make it simpler to add or remove stacked objects from your stillages without unloading the full consignment.

- Details

Lifting heavy items in a shop or warehouse is backbreaking and often unsafe work. It's also easily dealt with, provided you have the right equipment. When it comes to unloading, carrying bulky goods, and loading them on for storage, there's nothing like a hand truck to take that load off your hands. But are hand trucks worth the price tag compared with other transport solutions? In many cases, the answer is a resounding ‘yes’, and here are the main reasons why:

- Details

Falls from height in the workplace continue to be the main cause of industrial fatalities in the UK, accounting for approximately one quarter of deaths between 2013 and 2018. Additionally, in the same period there were over 5,000 injuries sustained from falls, some of which were serious or life-changing in nature. Most of these accidents involved falls from scaffolds, ladders, platforms, and roofs, so it is imperative that employers provide workers with suitable safety equipment to ensure they can carry out their duties safely and to comply with the Work at Height Regulations (2005).

- Details

If you're in charge of buying equipment for a warehouse or distribution business, you'll almost certainly come across the word "stillage" at some point. If you aren't sure what a stillage is, however, don't worry. In this post, we'll explain what stillages are, the types of stillages that you can buy, and why you should be using them.

- Details

Since gas is a highly flammable material, it’s essential to follow all safety recommendations to keep commercial spaces safe for workers and visitors. In this article, we offer an overview of the best practices in gas bottle storage, as well as information on why it’s good to invest in a gas bottle storage cage.

- Details

Spill containment pallets are effective at protecting surfaces from chemical spills and leaks. They are made of polyurethane or steel and can withstand a wide range of chemicals without causing corrosion or reactions. Steel pallets can handle the broadest range of corrosive substances and are the sturdier product – with a price that reflects this. Polyurethane pallets are cheaper and more commonly used, but are more easily damaged and cannot be used with certain highly corrosive substances.

- Details

A steel stillage is a sturdy and hardy form of support platform that's ideal for storing and transporting goods. They are usually manufactured from carbon steel with mesh cages to transport items. Stillages save time and reduce the risk of injury and damage to goods when compared to open wooden pallets. There are plenty of varieties to pick from too, from stackable stillages to frame stillages without walls for transporting large items like glass windows.

A typical stillage uses several types of structural steel for various components, and the material composition can vary between specialist stillages designed for different purposes.

- Details

A wire pallet cage is a storage container made out of steel bar grids. They're ideal for storing big items and bulky loads in warehouses, shops, and workshops. Folding wire pallet cages are collapsible - this can greatly reduce the footprint they occupy when they're placed in storage.

- Details

Wood is often thought of as the ultimate answer to sustainability, but the humble pallet can stack a lot of ecological headaches. Calculating carbon footprints is notoriously complex, so here are the boiled-down basics of how the Victorian-era wooden pallet performs on the modern stage!

Carbon Release

As trees grow, they absorb carbon, which is then locked into the wood. This removes CO2 from the atmosphere, which is important. However, the problem occurs at the end of the product lifecycle when the wood is frequently burned, releasing the stored greenhouse gasses back into the air. As such, wooden pallets are only environmentally neutral if a replacement tree is planted for each one, a practice that is extraordinarily rare. In contrast, metal can be melted and reused without releasing harmful levels of CO2, and without the need for expensive compensatory strategies.

Toxic Chemicals

As a bio environment, wood is home to multitudes of microorganisms. When they are shipped around the world, foreign bacteria, beetles, and fungi can disrupt ecosystems, leading to an import ban on untreated timber in many areas. Countries that still allow foreign-made pallets often have laws in place requiring the wood to be treated with chemicals such as methyl bromide. This highly toxic pesticide can cause seizures, comas, and irreversible neuromuscular and cognitive damage in humans, and releases methane into the environment. The latter is such a dangerous ozone-depleting greenhouse gas that methyl bromide is being phased out globally under the Montreal Protocol. In contrast, metal pallets have no requirement for toxic treatments, and are therefore globally welcomed.

Longevity

To make them economically viable, wooden pallets are made from thin, flimsy wood that usually survives just a single journey. There is a double irony in this, as most pallets are manufactured in East Asia and then shipped to the UK – a journey of up to a month – only to be used once, generating a staggering carbon footprint. Metal stillages, which can often be used and re-used for around seven years, represent a much more sustainable option.

- Details

Platforms, ladders, and stairs come in all shapes and sizes, but there are limitations to their use in warehouse and commercial settings. Safety is always essential when accessing materials on high shelves in the warehouse. While low-level positions can be easily reached with convenient step-level platforms, working at height requires more robust solutions. Here, ladders can be dangerous tools even though they’re essential for completing necessary tasks. Here’s why mobile platform ladders and steps are better and safety than typical ladders.

- Details

Order picking trolleys are the workhorses of order fulfilment in a warehouse setting. Widely used to help collect stock items from the shelves, they often consist of nothing more than a metal or plastic frame with inbuilt shelves or crates. Some models feature fold down step ladders, self-adjusting containers, or tiltable crates. What makes them so invaluable to people involved in materials handling, though?

- Details

If you are still dependent on wooden pallets in your warehouse, manufacturing, or distribution facility, there are plenty of reasons to upgrade to using steel stillages instead. Here are a few of the benefits you'll enjoy when you upgrade your equipment:

- Details

Effective organisation and use of space is vital in warehouses to ensure that goods can be picked, packed, and shipped quickly, helping optimise the supply chain and promote the accurate and rapid turnover of stock. Equally, the safety of warehouse operatives is paramount; the secure storage of goods can help to prevent accidents and promote productivity.

- Details

All industrial warehouses use ladders of some sort, so most warehouse managers are familiar with the terms ‘working height’ and ‘platform height’. Nonetheless, these terms refer to different things, which often confuses people who are looking to purchase new equipment for their business. The following information should allay this confusion, so you have the required knowledge to provide your staff with the tools they need.