- Home-

- Products-

- All Products

- --------------

- Mobile Steps

- Roll Pallets & Roll Cages

- Stillages & Pallet Cages

- Warehouse Platform Trolleys

- Pallet Converters & Pallet Retention

- Folding Wire Pallet Cages

- Container Ramps

- Plastic Pallet Boxes

- Aluminium & Glassfibre Ladders

- Tipping Skips

- Shopping Trolleys

- Plastic Trucks Skips & Bins

- Hanging Garment Rails

- Chute Front Stillages

- Garden Centre Trolleys

- Load Restraint Range

- Post Pallets

- Pallets

- Plastic Tote Boxes

- Sack Trucks

- Forklift Safety Access Cages

- Gas Bottle Storage & Cylinder Handling

- Spill Containment, Sump Pallets & Flooring, Storage of Hazardous Products

- Bulk Bag Holders and Handling

- Castors & Wheels

- Second Hand-

- CustomManufacture

- Rental-

- AboutUs

- Blog-

Featured Products

Products

- All Products

- Mobile Steps

- Roll Pallets & Roll Cages

- Stillages & Pallet Cages

- Warehouse Platform Trolleys

- Pallet Converters & Pallet Retention

- Folding Wire Pallet Cages

- Container Ramps

- Plastic Pallet Boxes

- Aluminium & Glassfibre Ladders

- Tipping Skips

- Shopping Trolleys

- Plastic Trucks Skips & Bins

- Hanging Garment Rails

- Chute Front Stillages

- Garden Centre Trolleys

- Load Restraint Range

- Post Pallets

- Pallets

- Plastic Tote Boxes

- Sack Trucks

- Forklift Safety Access Cages

- Gas Bottle Storage & Cylinder Handling

- Spill Containment, Sump Pallets & Flooring, Storage of Hazardous Products

- Bulk Bag Holders and Handling

- Castors & Wheels

Roll cages are the humble work horse of many distribution systems. Used by most retailers to transport goods to store, the roll pallet is available in many shapes and sizes. The roll cages also have many other uses in many different industries including storage and being used as picking cages.

When choosing a roll cage there are a few decisions to make. Firstly, what nesting configuration?

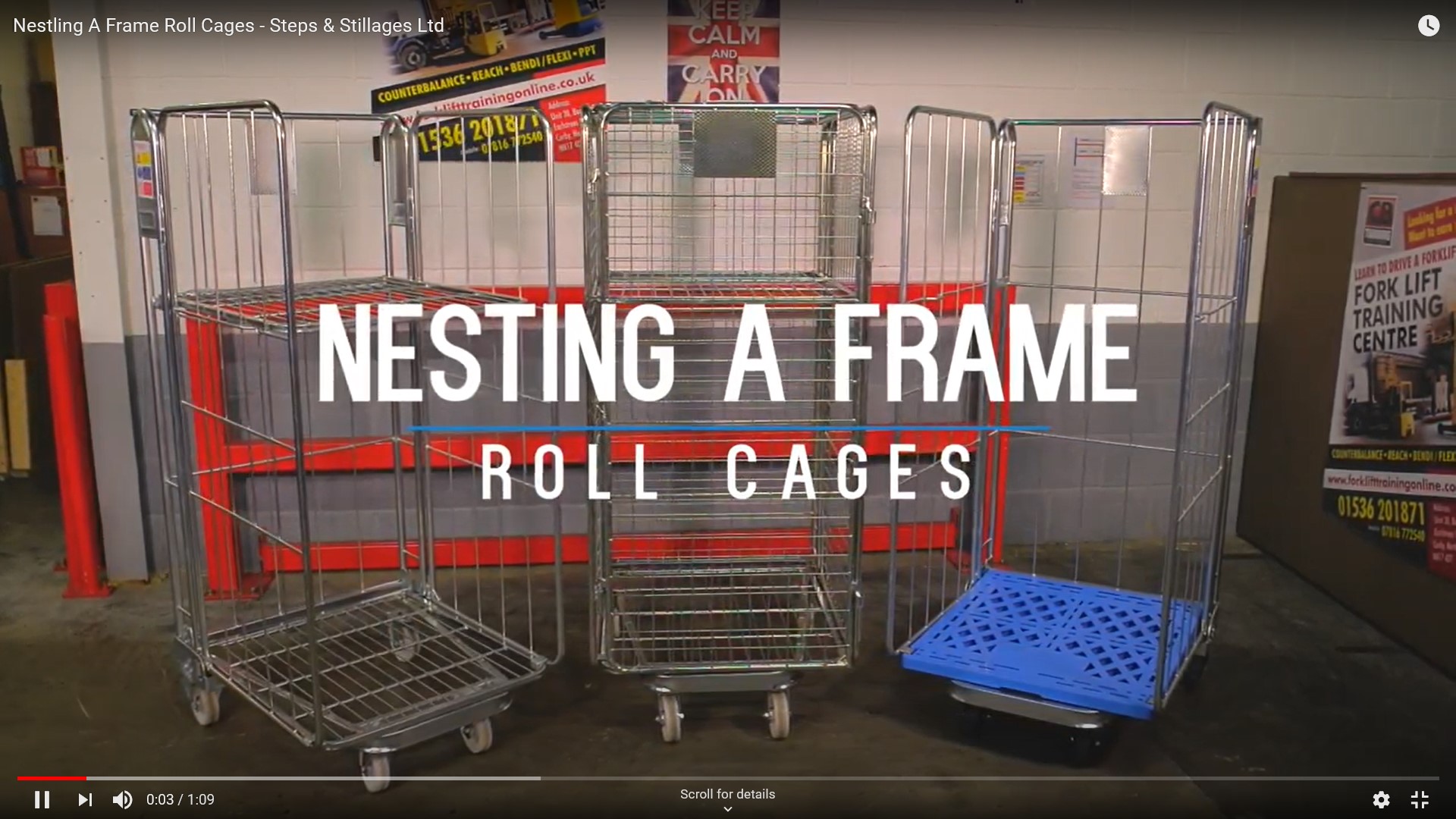

The "A" frame nesting cage is a UK standard cage. The sides fold up and the cages then nest into the back of each other, similar to a shopping trolley. The A frame style has good space saving properties with saving of 3:1 ratio.

"Z base" nesting is another roll pallet configuration. It is not as common, principally used by Tesco, but the roll pallet tends to be more stable as the wheels are on all 4 corners.

The final main configuration is a demountable cage. Demountable roll cages completely disassemble, so the sides lift off the base and can be stacked separately. That makes the demountable roll pallets very space saving efficient.

There are some other roll container nesting designs, but these tend to be bespoke or specific to a particular company or user.

Once the roll cage nesting design is established, next is the cage design. How many sides are required? A simple 2 sided cage is fine for some applications, but a 3 sided cage is more normal. A front door can be added to make a 4 sided roll cage, and a lid is used to make a full security roll pallet.

The roll container side infill now needs to be determined. A rod infill side has a coarse grid made from 6mm diameter vertical rods. This rod infill is fine for holding large boxes or items, alternatively, a mesh infill roll cage uses a 50mm x 50mm mesh panel which can secure smaller items or the full security cage prevents items from being stolen once the cage is sealed.

The final option are shelves for the roll pallet. A frame nesting cages can have an integral shelf fitted. This shelf is at a fixed height and cannot be moved. A loose roll cage shelf has hooks on each side which locate on the horizontal bars of the cage, or the individual strands of mesh on a mesh infill roll cage.